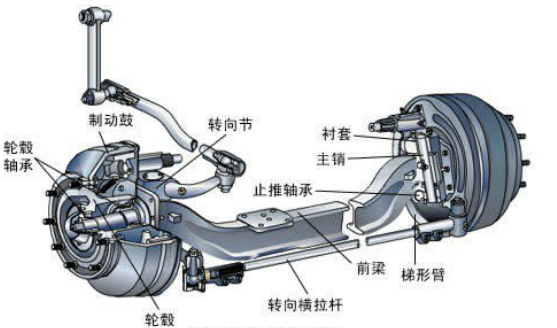

Assembly of Automotive Front Axle Steering System

(1) When installing the steering knuckle, appropriate adjustment shims should be selected and installed at the upper end of the front axle main pin hole, while thrust bearings should be installed at the lower end.

(2) Before installing the kingpin, use a Feeler gauge to check the clearance between the upper end face of the kingpin hole and the steering knuckle. If the clearance does not meet the specified value, add or remove the adjusting shim for adjustment.

(3) When installing the front axle main pin, a thin layer of lubricating grease should be applied to the surface of the main pin, the plane groove of the main pin should be aligned with the wedge shaped pin hole, and then a copper gun head or a wooden hammer should be used to gently tap in the main pin.

(4) After installing the transformed lock pin, tighten the lock nut with a torque of 19.6Nth. The length of the large end of the wedge pin exposed outside the hole should not be less than 2mm.

(5) After the kingpin is installed, check the tightness of the steering knuckle with a Spring scale.

(6) After installing the front axle assembly of the car, the horizontal and straight pull rods, wheel brakes, and other parts should be installed, and then the assembly quality should be checked. The ball pins of the horizontal and straight pull rods are required to rotate flexibly without jamming, and the connections between each part should be firm, and the dust prevention device should be intact and effective.

(7) Adjust the wheel brakes and front wheel toe-in, etc.